unit of hardness test|hardness conversion chart : purchasers An operator performing a Rockwell hardness test. (Source: Arkansas Department of Transportation.) The Rockwell hardness is calculated using the following formula: Rockwell Hardness, HRC = [0.2 – permanent . webMicro Macro Mundo Inc. Founded in 1986 in Miami Florida U.S.A. presents: The World best collection of products for your Hobby in Model Trains, Static plastic & wooden .

{plog:ftitle_list}

The deep down basic essence of the energy the numerology number 808 represents is analysis of everything that is available for inspection and study. Other meanings of the number 808 must take that resonance into .

The test provides numerical results to quantify the hardness of a material, which is expressed by the Brinell hardness number – HB. The Brinell hardness .

The Rockwell scale is a hardness scale based on indentation . The most common is the static load indentation hardness test, such as Brinell Hardness (HB), Rockwell Hardness (HRA, HRB, HRC), and Vickers Hardness (HV). These hardness values indicate the ability of a .

4 What is the unit of measurement for material hardness? 5 4 Test Methods for Determining Material Hardness. 5.1 The Brinell Test. 5.2 Rockwell Hardness Test. 5.3 Mohs Hardness .

An operator performing a Rockwell hardness test. (Source: Arkansas Department of Transportation.) The Rockwell hardness is calculated using the following formula: Rockwell Hardness, HRC = [0.2 – permanent . Hardness testing is a vital process in many industries. Our guide explains everything you need to know about this crucial technique. From testing methods to the key applications, we cover it all to help you stay informed. .What is Mohs Hardness Scale? The Mohs Hardness Scale is a set of ten reference minerals (numbered 1 through 10) that are used to determine the relative hardness of minerals and other objects. In this test the hardness of a .

ROCKWELL HARDNESS TESTING The Rockwell hardness test is a fast method, making it ideal for quick hardness testing. We give a definition of the Rockwell hardness test, as well as practical information of how to apply it in practice. The Rockwell hardness test at a glance: Generally used for larger samples ; No optical readout; Can be used for .2. Brinell Hardness Test Procedure. The Brinell Hardness Test is performed in a Brinell Hardness Test Unit. In this test method, a predetermined force (F) is applied to a tungsten carbide ball of fixed diameter (D), held for a predetermined time period, and then removed.Each unit must fall within an acceptable range of the specified hardness to meet quality standards. Moreover, these standardized hardness values facilitate comparisons among different materials, aiding in material selection tailored to meet specific application requirements. . Shore Hardness Test: Specifically designed for elastomers and .

Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and .Get all your information on Rockwell hardness testing from ZwickRoell Definition Advantages and disadvantages Examples More information. Jump to the content of the page. English. . The scale division (basis h0 for the residual indentation depth h to be measured is 100 or 130 units (depending on the scale, the following applies: 1 unit E = 0. . Hardness generally refers to the resistance of a material to scratching or indentation, and a qualitative measure of the strength of the material. The most commonly used hardness tests are the Rockwell test, Brinell test and the Vickers hardness test. This article will provide an introduction into durometer hardness and the gauge used to .16 Unit 2: Hardness Testing OBJECTIVE. After completing this unit, you should be able to: Perform a Rockwell Test; Perform a Brinell Test; Beyond verifying our in shop heat treatment, testing hardness is sometime necessary for production work as well. Even though it’s bad planning, occasionally a job arrives at our machine shop with an .

The Knoop hardness test / k . HK values are typically in the range from 100 to 1000, when specified in the conventional units of kg f ⋅mm −2. The SI unit, pascal, is sometimes used instead: 1 kg f ⋅mm −2 = 9.80665 MPa.Two inline skate wheels with different durometer – 85A and 83A Digital Shore hardness tester. The Shore durometer is a device for measuring the hardness of a material, typically of polymers. [1]Higher numbers on the scale indicate a greater resistance to indentation and thus harder materials. Lower numbers indicate less resistance and softer materials.

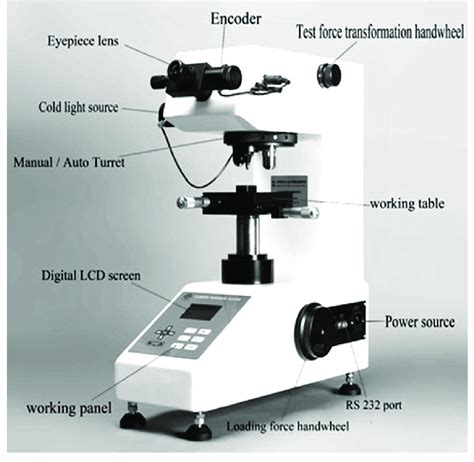

vickers hardness testing machine diagram

Hardness is an important property in engineering, manufacturing, and materials science as it affects a material's performance, durability, and lifespan. The hardness of a material can be determined through various tests, such as the Rockwell hardness test, Brinell hardness test, Vickers hardness test, and Knoop hardness test.Mohs hardness kit, containing one specimen of each mineral on the ten-point hardness scale. The Mohs scale (/ m oʊ z / MOHZ) of mineral hardness is a qualitative ordinal scale, from 1 to 10, characterizing scratch resistance of minerals through the ability of harder material to scratch softer material.. The scale was introduced in 1812 by the German geologist and mineralogist .According to the International System of Units, the units of measurement of tablet hardness mostly follow standards used in materials testing.. Kilogram (kg) – The kilogram is recognized by the SI system as the primary unit of mass. Newton (N) – The Newton is the SI unit of force; the standard for tablet hardness testing. 9.807 Newtons = 1 kilogram (at one G, earth surface .The Janka hardness test . This confusion is greatest when the results are treated as units, for example "660 Janka". [4] The Janka hardness test results tabulated below followed ASTM D 1037-12 testing methods. Lumber stocks tested range from 1" to 2" (25–50 mm) thick. The tabulated Janka hardness numbers are an average.

measurement thickness of fingernail

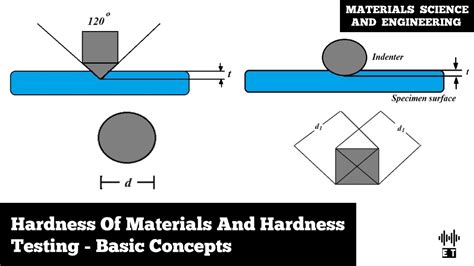

Brinell is also a common unit used for listing the hardness of steel materials. The test is done with a 10 millimeters steel ball pressed with 3000 kilogram-force (About 6,600 Libras). . Vickers is a common unit for measuring the .The hardness of rubber and elastomers according to Shore is determined using test procedures standardized in compliance with ISO 48-4 or ASTM D2240.. In the Shore hardness test, the indentation depth is measured using a spring-loaded indenter made of hardened steel to indent the material/specimen.The indentation depth is a measurement for Shore hardness, that is .

Brinell hardness test is an indentation hardness test.It uses a hard spherical ball (usually around 10mm in diameter). An applied force (a typical test will use 3,000 kilograms) pushes the ball against the surface of the material for a set amount of time (between 10 – 30 seconds, known as the dwell time).

measurement thickness thin film interference fringes

types of hardness testing methods

The Shore A hardness scale is widely used in the polymer and plastics industry to characterize the hardness of various materials. Manufacturers use durometer testing as a quality check for manufactured products. For example, silicone hardness or rubber hardness can easily be measured and evaluated against manufacturing standards.All our Brinell hardness test units are designed to deliver the long-term performance for which Struers is renowned. Duramin-4: Manual Micro and Micro/Macro Hardness Testing Machine Load ranges: 10 gf – 2 kgf and 1 kgf – 62.5 kgf.The Vickers hardness test is suitable for a wide range of applications, including micro hardness testing. On this page, you can find a description of the Vickers hardness test, practical information on how to apply it and a list of our micro hardness testing machines for Vickers. The Vickers hardness test at a glance: Ideal for micro hardness .

The governing standard for the Barcol hardness test is ASTM D 2583. [4] Barcol hardness is measured on a scale from 0 to 100 with the typical range being between 50B and 90B. A measurement of 60B is roughly equivalent to a Shore hardness of 80D or .

PORTABLE HARDNESS TESTING UNIT. 2. HH-411 is a compact portable hardness tester that is user-friendly. A single touch of a button performs the non-destructive impact hardness . test so it's extremely easy to test workpieces on site. Equipped with data storage function.Water hardness is measured in terms of a unit called “parts per million” (ppm) or “milligrams per liter” (mg/L). There are two main methods of measuring water hardness: titration and test strips. . The test strips method is a simpler and quicker way to measure water hardness. The test strips are coated with a reactive material that .GPG water hardness unit denotes how many grains of CaCO3 are dissolved in 1 US gallon. 1 grain of CaCO3 is equal to 64.8 mg of CaCO3, and the US gallon is equal to 3.79 liters. Here is a test tube with 5g of CaCO3 from our lab. These 5 grams are equal to 77 grains of CaCO3.

This dial like scale is really a depth gauge, graduated in special units. The Rockwell hardness test is the most used and versatile of the hardness tests. For soft materials such as copper alloys, soft steel, and aluminum alloys a 1/16" diameter steel ball is used with a 100-kilogram load and the hardness is read on the "B" scale. .

standard hardness test methods

webRedeem Code. Verification break. Submit. Update Required to Redeem. Check the App Store and update if prompted to avoid losing your code once entered.

unit of hardness test|hardness conversion chart